Excellence in innovation

LignumPlast – a leading producer of food packaging for end consumers and the HoReCa segment with full-cycle production and a high level of vertical integration.

Our company manages every stage of production – from raw material selection to the creation of finished products – ensuring exceptional quality, flexibility, and a tailored approach to meet our clients’ needs. Thanks to our vertical integration, we guarantee process efficiency and quick adaptation to market demands, maintaining our position as a reliable partner for businesses.

Cling film

LignumPlast specializes in the production of high-quality food cling film and baking paper, which are manufactured both for private labels of retail chains and for well-known global brands.

We implement innovative solutions at every stage of production.

Modern equipment guarantees impeccable quality, ease of use, and flexibility in fulfilling orders of any complexity.

Our approach allows us to quickly adapt to changing customer needs and create products that meet the highest standards.

Our cling film is the result of our own developments. The multilayer structure provides excellent consumer properties, and the static charge when unrolling adds a sticky effect, making it indispensable in everyday use.

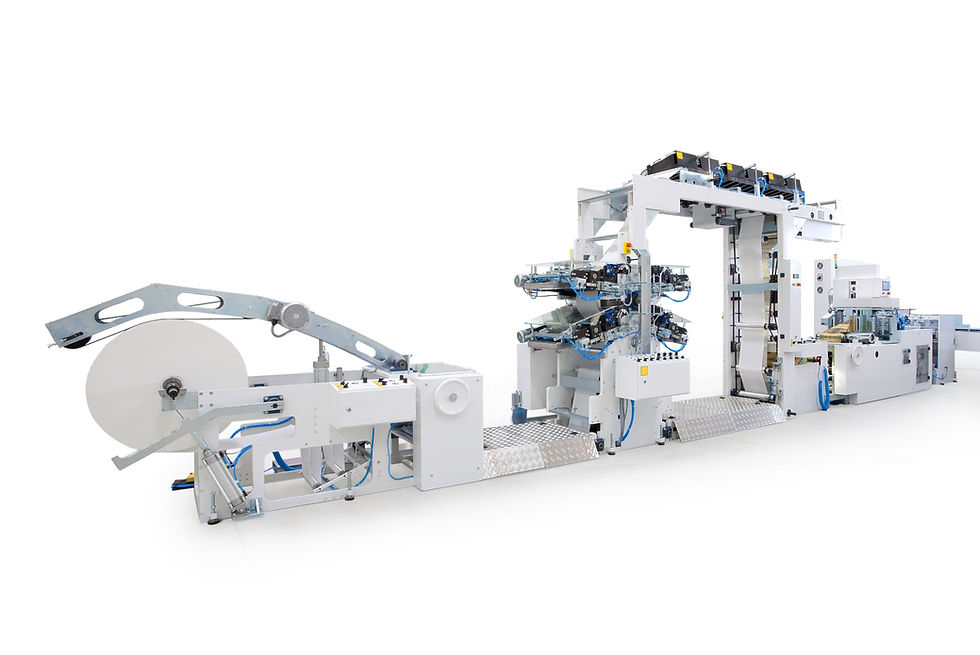

The production process at our enterprise is maximally automated to ensure stable product quality, efficiency, and flexibility.

Each stage is performed by modern automated systems that minimize human intervention and ensure high processing speed.

1. Extrusion process:

The raw material enters the extruder, where a multilayer film is formed according to unique formulations. The system automatically adjusts temperatures, pressures and process speeds to achieve the ideal thickness and structure of the material.

2. Winding:

The finished film from the extruder is automatically wound onto rollers. Special sensors monitor the uniformity of the winding to ensure accurate weight and length of the rolls.

3. Packaging line:

The wound rolls are automatically transported to the packaging line.

Robotic systems:

• Form boxes from cardboard.

• Automatically place film rolls into prepared packaging.

• The boxes are closed and placed in an SRP box (Shelf Ready Packaging), ready for sale.

4. Palletizing:

Completed packages arrive at the palletizing station, where a robot automatically places boxes on pallets according to a predetermined pattern.

The pallets are then wrapped in stretch film for safe transportation.

Result:

Full automation ensures high productivity, minimizes the human factor and allows us to quickly fulfill orders even in conditions of high demand. This allows us to remain a reliable partner for customers with high requirements for quality and delivery times.

Baking paper

Lignum Plast – the only producer of baking paper in Ukraine offering innovative solutions for businesses.

Thanks to our unique silicone coating technology applied to kraft paper, we create high-quality products that meet the stringent standards of the food industry and the demands of the modern market.

The Baking Paper Production Process

Our manufacturing process consists of several key stages:

1. First, we prepare kraft paper to enhance its properties and ensure high quality.

2. Next,silicone coating: Using our proprietary technology, we apply a silicone coating that ensures resistance to high temperatures and prevents sticking.

3. Final stage,quality control: The final stage involves rigorous quality checks to ensure that every sheet or roll meets our high standards.

Why Choose Us?

• Versatility: Our baking paper is suitable for both professional use in restaurants, bakeries, and factories, as well as for everyday household needs.

• Customization: We can create baking paper with your unique design or print universal patterns for the mass market.

• Flexibility in production: Products are available in rolls or sheets to meet the specific requirements of your business.

• Wide range: We offer baking paper in various formats, densities, sizes, colors, and packaging options to perfectly match your business needs.

How We Work

The entire production process – from preparing kraft paper to silicone coating and final processing – is fully supervised by our specialists. This ensures consistently high product quality that meets the needs of both retailers and end consumers.

Lignum Plast – your trusted partner in premium baking paper production.

Aluminum foil

The company is equipped with equipment that allows it to produce both standard rolls of aluminum foil in various types of packaging, as well as embossed foil thanks to special additional equipment.

This provides the ability to produce foil with embossing - both with universal patterns and with individual designs or customer logos.

Oven sleeve

Oven sleeve from Lignum Plast - a modern solution for healthy and convenient cooking

Our company produces a high-quality baking sleeve from a special heat-resistant film made of modified polyethylene terephthalate (PET). Thanks to this material, the sleeve can withstand temperatures up to 220°C, ensuring safety and ease of use.

We produce baking sleeves in various packaging options: in a box, in flexible packaging, with or without clips, and with different types of seams to meet the needs of each customer.

This product is ideal for healthy eating.

Quality control

Responsibility

This section presents the company's corporate policies that regulate activities in the areas of product quality and safety management, compliance with ethical norms and principles of responsible business conduct, occupational health and safety of employees, and prevention of the use of child labor and modern slavery.

Corporate Policies

Complaints and appeals

Supplier Information

LignumPlast is a modern production site specializing in creating products under our clients' brands.

We collaborate with leading global brands and retail chains, providing an individual approach to each order.

Contact us to find out how we can create products under your brand name or help improve and expand the range of your existing line.

Your brand is our responsibility. Every day we work to exceed your expectations and justify the trust you place in us.

LignumPlast is your partner in creating quality that consumers value.

We are trusted